Well, it’s been another lockdown- fast becoming the no. 1 past time for the Great British Public- and so understandably work at Blyth Road has more or less ground to a halt again. Mind you, the general trend down there at the moment is one of damp, chilliness and frost, which whilst sometimes picturesque, is less jolly to work in.

This was the rather wintry scene on Friday morning as I arrived. I think judicious use of the sanders might be indicated in these conditions, but it does go to show how the tracklaying has been progressing prior to lockdown. The volunteers will – hopefully- return next week, in limited numbers according to whatever further restrictions may apply to the area. Nota Bene to anyone hoping to join us- places will still need to be ‘booked’, so if you’re planning to come and volunteer on any given day, do ring ahead and book in on the Trust’s number.

This was the rather wintry scene on Friday morning as I arrived. I think judicious use of the sanders might be indicated in these conditions, but it does go to show how the tracklaying has been progressing prior to lockdown. The volunteers will – hopefully- return next week, in limited numbers according to whatever further restrictions may apply to the area. Nota Bene to anyone hoping to join us- places will still need to be ‘booked’, so if you’re planning to come and volunteer on any given day, do ring ahead and book in on the Trust’s number.

Other work in hand prior to the cessation of activities involve fitting guttering to the locomotive shed and preparing areas for the planting of around 150 new trees given to us by the Woodland Trust, so more news will be due on these fronts in due course.

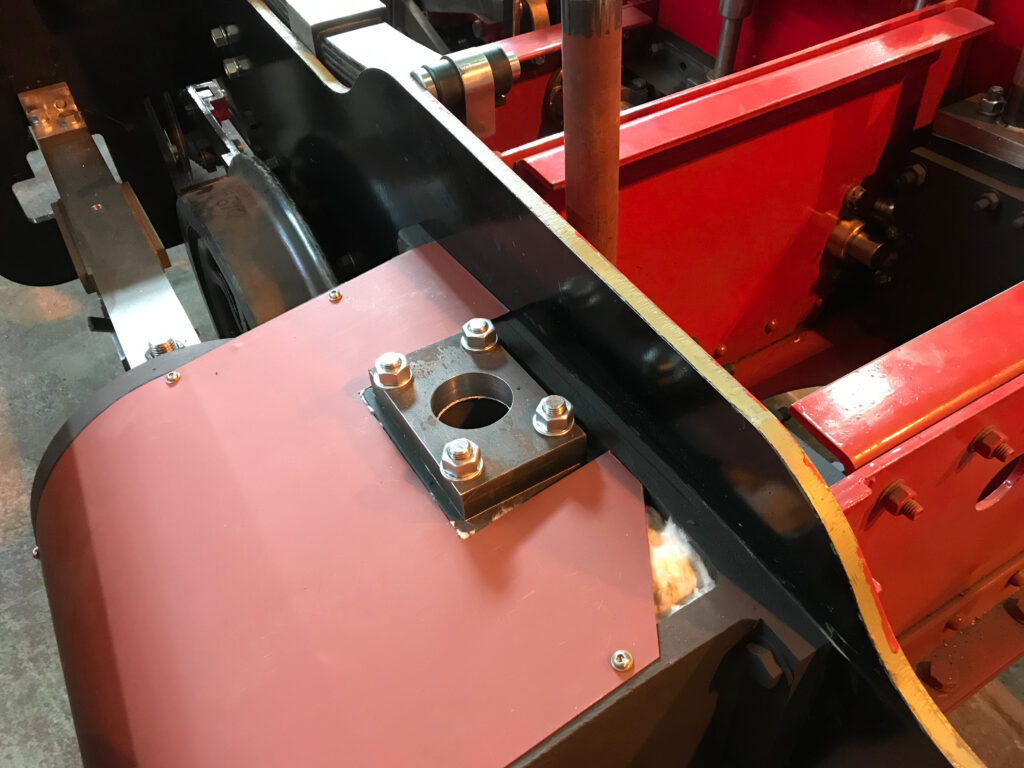

Whilst we at Steamworks have been limited in what we can do, the same does not apply to North Bay Engineering, who have been making great strides in the construction of Blyth. During this time they have completed and assembled all those partially-shaped bits of steel and brass into the motionwork and valve gear, all of which have now been fitted to the frames- see above- meaning that in theory, the bottom end of the loco can run for the first time on compressed air.

I say ‘in theory’, as it in fact requires not only quite a high pressure of air, but also a high volume of it, which in turn means a large pressure vessel is needed to contain a plenum of compressed air sufficient to turn the engines over. North Bay do not have a compressor tank large enough to achieve this, but fortunately, there was something on hand that might just do the job..

Yes, that’s the boiler- its first trial fit into the frames, with the intention of using it as a pressure vessel (well, it is a pressure vessel, after all) so that the locomotive can turn a wheel for the first time, via the regulator and plumbing to the steam chests. This is quite a step forward for the project, and also for the Trust- and just goes to show how close we now are to having an operating 2-4-0 in Southwold once more. It’s only been 91 years, after all.

Before this can happen though, NBRES intend to lag the boiler in timber (for insulation purposes- it’s not quite as mad as it sounds) and fit the steel cladding plates around the outside, so that when the boiler is in situ and plumbed in, there is no need for it to come out again. Understandable, as I doubt it’s a featherweight.

So far, we’re still on target for a delivery date in May/June for next year- in time for our usual open season in 2021, if indeed circumstances permit us to have one. What a post-Covid comeback that would be! We have sufficient funds to commence the final stage, which will begin with the fabrication of plate work and include all the peripheral fittings, couplings and draw gear, sanders (see comment about frosty rails above), painting and lining and so on and so on. To complete everything and still remain on target, however, we will need to arrange a further £80,000 to see Blyth ‘home’ for 2021. To this end we will be shortly launching an appeal for donations via the heritage railway press, but there’s no harm in mentioning it here, too! All contributions are welcome, and can be made either by post to the Trust’s Steamworks address, or on the ‘Project Blyth’ page of this website.

Fingers crossed for the New Year!

Oliver