A small team of Trust volunteers worked on both locomotives, recently. The frames of Sharp Stewart 2-4-0T “Blyth” were unbolted from the stretchers and buffer beams, ready for transporting to Peggs of Aldeburgh for the rest of the work to be done, now we have a full 3D CAD design.

This left a nice big space (something that our workshop never has enough of) into which Motor Rail Bo “Mells” could be moved, thus leaving space elsewhere for the imminent arrival of the parts of open wagon 41’s underframe. Musical chairs have nothing on the Rolling Stock Group

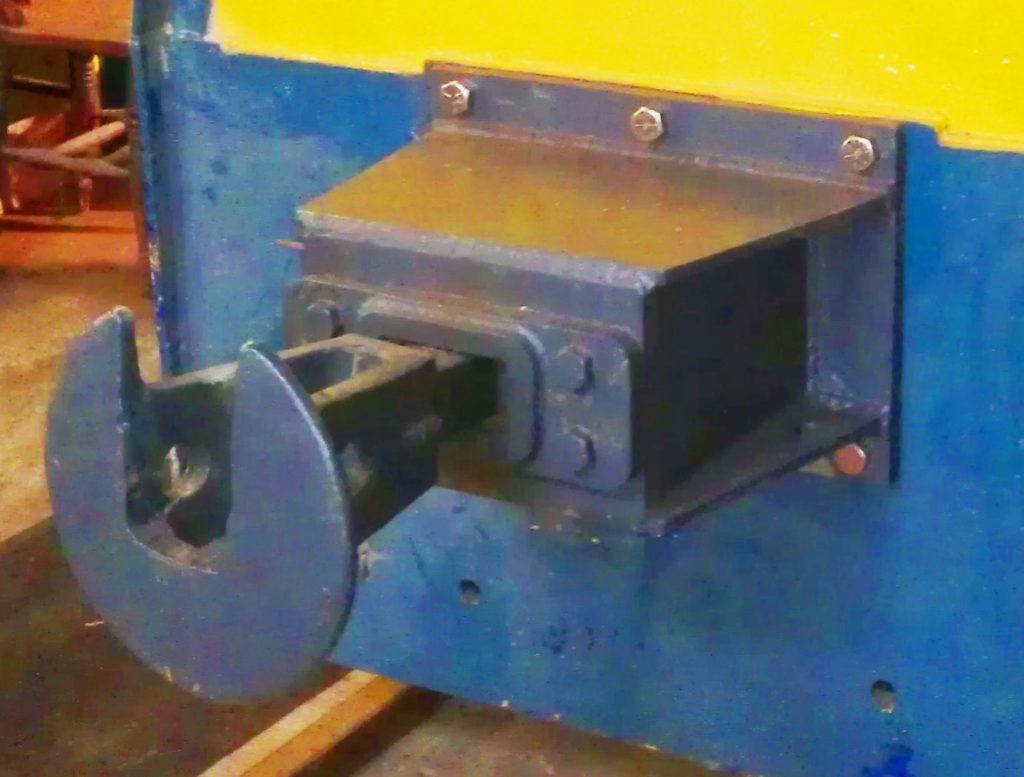

It seemed easier to complete the brake and sander assemblies while the loco was up in the air – so Bob, as usual on his back on the floor, first fitted the second sander which we had made, with only a little tweak on one bolt hole –and then the RHS brakes, which have not been attached to the loco for some time.

There was a certain amount of suppressed imprecation to be heard – the brakes are extremely heavy, and the pivots and actuator not very logically designed – but the job was done, even including the nifty little cover plate which Motor Rail only fitted, oddly, on one side. We then greased and eased all the sander and brake mechanisms, adjusted up the brakes (with the help of an oddly tiny allen key) – and everything works! So we dropped the loco onto the “track” panel (actually a welded square-section steel panel, being easier to handle than real rail), and – with a long lever and some muscle – moved it to the end of the workshop.

Meanwhile, James was putting the new flexible exhaust pipe and elbow together (it’s not pretty, but it works), trial-refitting one of the cab grab handles, and making the new cab floor – out of recycled decking, kindly supplied by John Bennett.

He also, as always, painted everything in sight (and out of sight) in heatproof JCB yellow – a nasty habit he has, particularly when you need to use a part, and find it is very wet indeed. The yellow, by the way, does not come off skin, being very adhesive.

On Bank Holiday Monday James was tasked with opening the workshop (under strictly controlled conditions) to the public on the Classic Bus Tour – so it seemed useful to get some work done as well. Apart from (of course) painting everything yellow which had not yet been painted yellow, and painting a second coat on those things that had already been yellowed – he completed the aluminium checker-plate cover in the cab. This protects the battery, and is extended to fill the hole where the secondary take-off system used to come through. The aluminium, sourced by Chris from Mackays of Cambridge, had to be bent to a right-angle, which took a great deal of very noisy hammer-work: luckily, nearly everyone was at the Fete on the common – or perhaps they just didn’t want to complain to someone swinging such a large hammer with such abandon?